- 5005 Aluminum Block

- 5052 Aluminum Block

- 5083 Aluminum Block

- 5086 Aluminum Block

- 5182 Aluminum Block

- 5454 Aluminum Block

- 5754 Aluminum Block

- 6061 Aluminum Block

- 6063 Aluminum Block

- 6082 Aluminum Block

- 1060 Aluminum Block

- 2024 Aluminum Block

- 2A12 Aluminum Block

- 7005 Aluminum Block

- 7075 Aluminum Block

- 3003 Aluminum Block

NEWS

INFORMATIONTel:

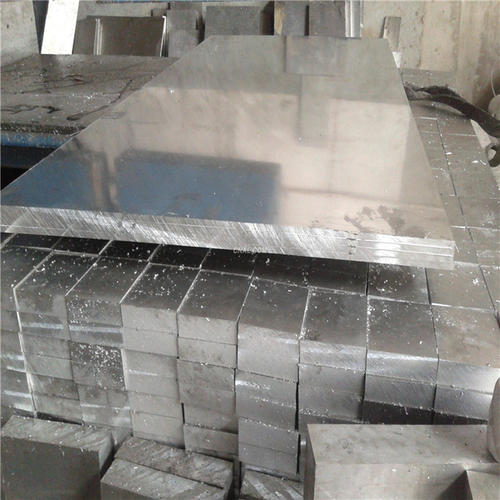

86 173448944907055 T74511 T7751 Aircraft grade Aluminum Plate block Bar

Last Updated :2023/06/13

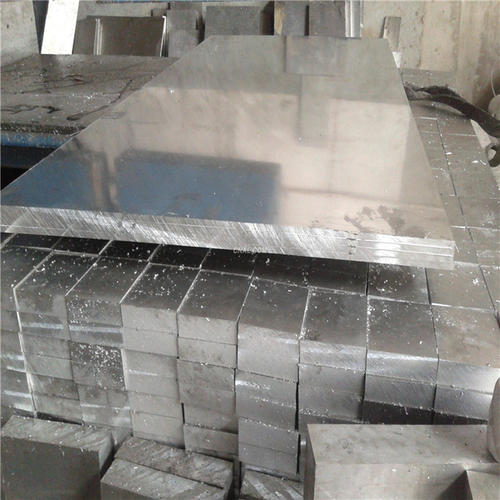

Introduction of 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar:

7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar is a new type of alloy developed to meet the increasing demand for high-quality aluminium materials in aerospace industry, automobile manufacturing industry and electronics industry. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has low density, high strength, good processability, good welding performance and good welding performance. Stress corrosion resistance is widely used in aerospace and other fields. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar

is an outstanding representative of the new high strength aluminium alloy. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar is a new type of aluminium alloy developed on the basis of 7050 aluminium alloy, which increases the content of zinc and copper and reduces the content of Fe and Si impurities. The results show that the 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has higher strength and stronger fracture toughness than 7050 aluminium alloy plate, so it has wide application prospects.

Chemical composition of 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar:

Si:0.10

Fe:0.15

Cu:2.0-2.6

Mn:0.05

Mg:1.8-2.3

Cr:0.04

Zn:7.6-8.4

Ti:0.06

Al:Remainder

Compared with die steel, 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has obvious advantages:

1. Light weight. Because its density is only 36% of the general die steel, the inertia of motion is relatively low. It is easy to accelerate and decelerate in the production process, which can reduce the loss of machine and die.

2. Machining is easy and dimensional stability is high. Its cutting speed is more than 6 times faster than that of the general die steel, so the processing time of the die is greatly reduced and the die can be produced faster.

3. Excellent heat conductivity. The heat conductivity of the die steel is higher than that of the common die steel, so the cold cutting time of the die during production can be saved by 50%, thus improving the production efficiency of the die. So Alumold is widely used in 80% of the products of injection mold, blow mold, low pressure mold, rubber mold and other different mold industries.

7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar is a new type of alloy developed to meet the increasing demand for high-quality aluminium materials in aerospace industry, automobile manufacturing industry and electronics industry. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has low density, high strength, good processability, good welding performance and good welding performance. Stress corrosion resistance is widely used in aerospace and other fields. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar

is an outstanding representative of the new high strength aluminium alloy. 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar is a new type of aluminium alloy developed on the basis of 7050 aluminium alloy, which increases the content of zinc and copper and reduces the content of Fe and Si impurities. The results show that the 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has higher strength and stronger fracture toughness than 7050 aluminium alloy plate, so it has wide application prospects.

Chemical composition of 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar:

Si:0.10

Fe:0.15

Cu:2.0-2.6

Mn:0.05

Mg:1.8-2.3

Cr:0.04

Zn:7.6-8.4

Ti:0.06

Al:Remainder

Compared with die steel, 7055 T74511 T7751 Aircraft grade Aluminum Plate block Bar has obvious advantages:

1. Light weight. Because its density is only 36% of the general die steel, the inertia of motion is relatively low. It is easy to accelerate and decelerate in the production process, which can reduce the loss of machine and die.

2. Machining is easy and dimensional stability is high. Its cutting speed is more than 6 times faster than that of the general die steel, so the processing time of the die is greatly reduced and the die can be produced faster.

3. Excellent heat conductivity. The heat conductivity of the die steel is higher than that of the common die steel, so the cold cutting time of the die during production can be saved by 50%, thus improving the production efficiency of the die. So Alumold is widely used in 80% of the products of injection mold, blow mold, low pressure mold, rubber mold and other different mold industries.