- 5005 Aluminum Block

- 5052 Aluminum Block

- 5083 Aluminum Block

- 5086 Aluminum Block

- 5182 Aluminum Block

- 5454 Aluminum Block

- 5754 Aluminum Block

- 6061 Aluminum Block

- 6063 Aluminum Block

- 6082 Aluminum Block

- 1060 Aluminum Block

- 2024 Aluminum Block

- 2A12 Aluminum Block

- 7005 Aluminum Block

- 7075 Aluminum Block

- 3003 Aluminum Block

NEWS

INFORMATIONTel:

86 17344894490Aluminum engine blocks

Last Updated :2023/06/13

The advantage of the all-aluminum engine is light weight, which saves fuel by reducing weight. In an engine of the same displacement, the use of an aluminum block engine can reduce the weight of about 20 kilograms. For every 10% reduction in vehicle weight, fuel consumption can be reduced by 6% to 8%.

At present, the cylinder block of gasoline engine is divided into cast iron and cast aluminum. In diesel engines, cast iron cylinder blocks account for the vast majority. In recent years, with the rapid development of the automobile industry, sedans have rapidly entered the life of ordinary people, and at the same time, the fuel-saving performance of vehicles has gradually been paid attention to.

Reducing the weight of the engine can save fuel. The use of cast aluminum cylinder block can reduce the weight of the engine.

Aluminum engine block advantage

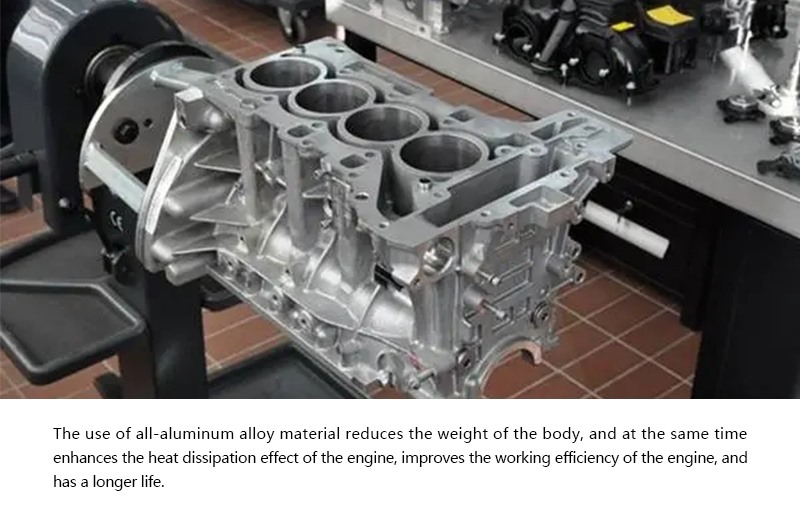

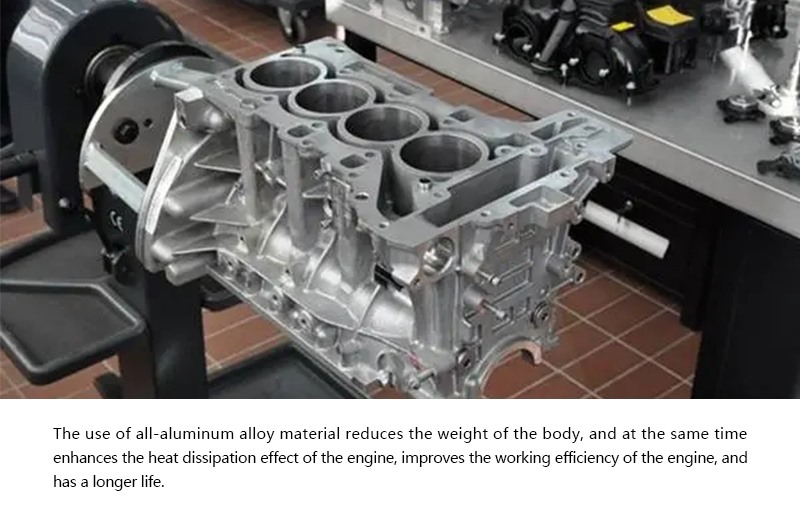

From the perspective of use, according to the latest data, the weight of foreign cars has been reduced by 20% to 26% compared with the past. For example, Fox adopts all-aluminum alloy material, which reduces the weight of the body, and also enhances the heat dissipation effect of the engine, improves the working efficiency of the engine, and has a longer life. From the perspective of fuel saving, the advantages of cast aluminum engines in fuel saving have attracted much attention.

In addition to the difference in weight, there are many differences in the production process between cast iron cylinder blocks and cast aluminum cylinder blocks. The cast iron production line occupies a large area, pollutes the environment, and the processing technology is complicated; while the production characteristics of the cast aluminum cylinder block are just the opposite. From the perspective of market competition, the cast aluminum cylinder block has certain advantages.

Iron and aluminum have different physical properties. The heat load capacity of the cast iron cylinder block is stronger, and the potential of cast iron is greater in terms of engine liter power. For example, a 1.3-liter cast iron engine can output more than 70kW, while a cast aluminum engine can only reach 60kW. It is understood that the 1.5-liter displacement cast aluminum engine can meet the power requirements of the 2.0-liter displacement engine through turbocharging and other technologies, while it is difficult for the cast iron cylinder engine to meet this requirement. Therefore, many people can also produce amazing torque output when driving the Focus at low speed, which is not only conducive to the start and acceleration of the vehicle, but also can shift gears earlier to achieve the effect of fuel saving.

A part of the aluminum block engine still uses cast iron materials, especially the cylinders, to use cast iron materials. The thermal expansion rate of cast aluminum and cast iron is not uniform after fuel combustion, which is commonly referred to as the problem of deformation consistency. This is a difficult problem in the casting process of cast aluminum cylinders. When the engine is working, the cast aluminum block engine equipped with the cast iron cylinder must meet the sealing requirements. How to solve this problem is a special concern of cast aluminum cylinder enterprises.

Manufacturers who are good at promoting their products often use the "dazzling" halo of "all-aluminum engine" to take the lead when promoting their auto products. In view of this, we can see that whether it is Audi A8, Focus, or Swift, the highlights of their engines are locked on the material of the all-aluminum cylinder block. It is undeniable that the all-aluminum engine is indeed superior to the cast iron engine in terms of material and heat dissipation.

At present, the cylinder block of gasoline engine is divided into cast iron and cast aluminum. In diesel engines, cast iron cylinder blocks account for the vast majority. In recent years, with the rapid development of the automobile industry, sedans have rapidly entered the life of ordinary people, and at the same time, the fuel-saving performance of vehicles has gradually been paid attention to.

Reducing the weight of the engine can save fuel. The use of cast aluminum cylinder block can reduce the weight of the engine.

Aluminum engine block advantage

From the perspective of use, according to the latest data, the weight of foreign cars has been reduced by 20% to 26% compared with the past. For example, Fox adopts all-aluminum alloy material, which reduces the weight of the body, and also enhances the heat dissipation effect of the engine, improves the working efficiency of the engine, and has a longer life. From the perspective of fuel saving, the advantages of cast aluminum engines in fuel saving have attracted much attention.

In addition to the difference in weight, there are many differences in the production process between cast iron cylinder blocks and cast aluminum cylinder blocks. The cast iron production line occupies a large area, pollutes the environment, and the processing technology is complicated; while the production characteristics of the cast aluminum cylinder block are just the opposite. From the perspective of market competition, the cast aluminum cylinder block has certain advantages.

Iron and aluminum have different physical properties. The heat load capacity of the cast iron cylinder block is stronger, and the potential of cast iron is greater in terms of engine liter power. For example, a 1.3-liter cast iron engine can output more than 70kW, while a cast aluminum engine can only reach 60kW. It is understood that the 1.5-liter displacement cast aluminum engine can meet the power requirements of the 2.0-liter displacement engine through turbocharging and other technologies, while it is difficult for the cast iron cylinder engine to meet this requirement. Therefore, many people can also produce amazing torque output when driving the Focus at low speed, which is not only conducive to the start and acceleration of the vehicle, but also can shift gears earlier to achieve the effect of fuel saving.

A part of the aluminum block engine still uses cast iron materials, especially the cylinders, to use cast iron materials. The thermal expansion rate of cast aluminum and cast iron is not uniform after fuel combustion, which is commonly referred to as the problem of deformation consistency. This is a difficult problem in the casting process of cast aluminum cylinders. When the engine is working, the cast aluminum block engine equipped with the cast iron cylinder must meet the sealing requirements. How to solve this problem is a special concern of cast aluminum cylinder enterprises.

Manufacturers who are good at promoting their products often use the "dazzling" halo of "all-aluminum engine" to take the lead when promoting their auto products. In view of this, we can see that whether it is Audi A8, Focus, or Swift, the highlights of their engines are locked on the material of the all-aluminum cylinder block. It is undeniable that the all-aluminum engine is indeed superior to the cast iron engine in terms of material and heat dissipation.