- 5005 Aluminum Block

- 5052 Aluminum Block

- 5083 Aluminum Block

- 5086 Aluminum Block

- 5182 Aluminum Block

- 5454 Aluminum Block

- 5754 Aluminum Block

- 6061 Aluminum Block

- 6063 Aluminum Block

- 6082 Aluminum Block

- 1060 Aluminum Block

- 2024 Aluminum Block

- 2A12 Aluminum Block

- 7005 Aluminum Block

- 7075 Aluminum Block

- 3003 Aluminum Block

NEWS

INFORMATIONTel:

86 17344894490Microstructure and Mechanical Properties of Aluminum Block A

Last Updated :2023/06/13

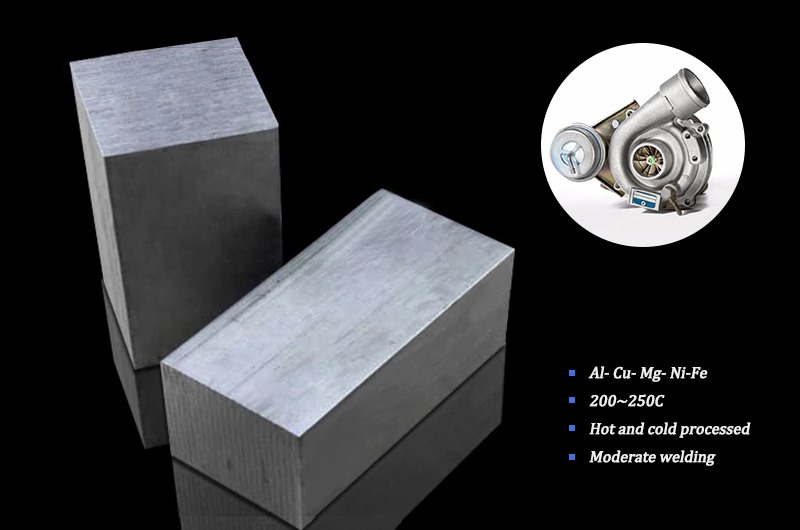

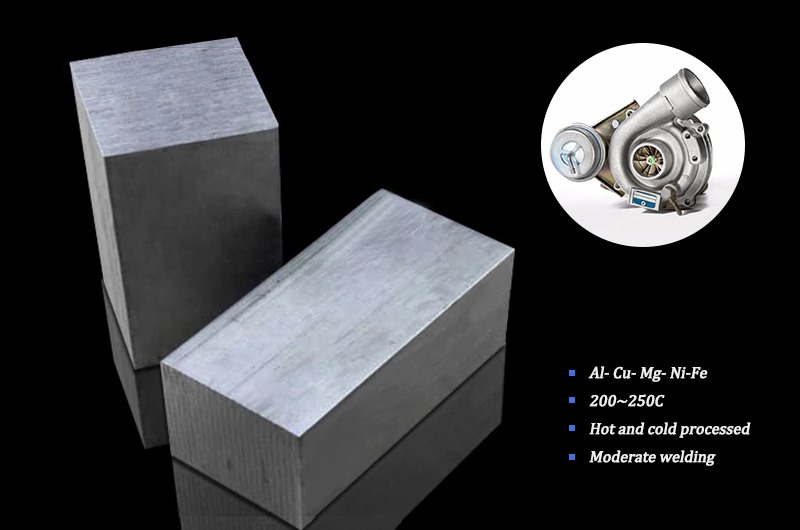

Aluminum Block Alloy 2618 has high heat resistance, the operating temperature is 200~250C, the cold and hot processing performance is good, and the welding performance is moderate. It is suitable for manufacturing parts used at higher temperatures, such as automotive turbochargers.

Aluminum Block Alloy 2618 is a heat-strengthened Al- _Cu- _Mg-Ni-Fe based alloy. The alloy has high heat resistance, the operating temperature is 200~250C, the cold and hot processing performance is good, and the welding performance is moderate. It is suitable for manufacturing parts used at higher temperatures, such as turbochargers for automobiles. The annual demand for turbochargers for automobiles is large (tens of millions). Due to the high operating temperature (200C) and high rotational speed of this product, the requirements for the fatigue properties of the material are very high.

A semi-continuous casting method was used to prepare the Aluminum Block Alloy 2618 ingot. Since most of the alloy products are used to manufacture important parts, attention should be paid to maintaining the purity of the metal during the smelting process. During the operation, attention should be paid to the introduction of gas and non-metallic inclusions into the melt, and at the same time, the refining and removal of the melt should be strengthened. Air and filter. During the smelting process, Fe and Ni in the alloy easily form the segregation and agglomeration of intermetallic compounds. For this reason, the content of Fe and Ni should not be too high, and should be controlled at the middle and lower limits.

The Aluminum Block Alloy 2618 ingot was prepared by semi-continuous casting method. The results showed that the chemical composition of the alloy was qualified, and the second phase FeNiAl9 and the precipitation phase CuMgAl2 were evenly distributed in the microstructure, which provided a guarantee for the heat resistance of the 2618 aluminum alloy.

Aluminum Block Alloy 2618 is a heat-strengthened Al- _Cu- _Mg-Ni-Fe based alloy. The alloy has high heat resistance, the operating temperature is 200~250C, the cold and hot processing performance is good, and the welding performance is moderate. It is suitable for manufacturing parts used at higher temperatures, such as turbochargers for automobiles. The annual demand for turbochargers for automobiles is large (tens of millions). Due to the high operating temperature (200C) and high rotational speed of this product, the requirements for the fatigue properties of the material are very high.

A semi-continuous casting method was used to prepare the Aluminum Block Alloy 2618 ingot. Since most of the alloy products are used to manufacture important parts, attention should be paid to maintaining the purity of the metal during the smelting process. During the operation, attention should be paid to the introduction of gas and non-metallic inclusions into the melt, and at the same time, the refining and removal of the melt should be strengthened. Air and filter. During the smelting process, Fe and Ni in the alloy easily form the segregation and agglomeration of intermetallic compounds. For this reason, the content of Fe and Ni should not be too high, and should be controlled at the middle and lower limits.

The Aluminum Block Alloy 2618 ingot was prepared by semi-continuous casting method. The results showed that the chemical composition of the alloy was qualified, and the second phase FeNiAl9 and the precipitation phase CuMgAl2 were evenly distributed in the microstructure, which provided a guarantee for the heat resistance of the 2618 aluminum alloy.